I made this tenoning jig from plans I picked up at the woodworking show in

Tampa March of 2003. It's made from Birch plywood, and has two coats

of Tung Oil.

|

|

|

|

|

|

|

|

First Step |

|

I cut the dadoes first, then made the cut to separate the top and bottom to ensure the grooves would perfectly line up. Instead of using Masonite for the runners, I used two strips of 1/8" Plexiglass, and epoxied them into the sliding platform |

|

|

|

|

|

|

|

|

|

|

|

|

Next, I cut a dado in the vertical face to receive the sliding platform, being extremely carefull to make a good-fitting groove, and to make sure that the face is at 90 deg. to the platform. It pays to be accurate here. |

|

|

|

|

|

|

|

|

|

|

|

|

Adding the two support braces will lend additional stifness to the vertical face. |

|

|

|

|

|

|

|

|

|

|

|

|

|

A hole had to be drilled to accept the threaded rod for the sliding mechanism...I first drilled the rear hole with the block clamped in place, then transferred the block to the front. A 90 deg. drill attachment made this go quite easily. |

|

|

|

|

|

|

|

|

|

|

|

|

I happened to have some UHMW material available, so I used it instead of regular hardwood, which the plans called for. Two of them for use on my BT3000 slot table virtually eliminates any sloppiness! |

|

|

|

|

|

|

|

|

|

|

Another view of the bottom slide rails |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The handle is made, by drilling two 1 1/4" holes, and routing all the edges to smooth things out a bit, and added the threaded rod slide adjustment. You can also see the vertical wood stop on the front face. |

|

|

|

|

|

|

|

|

|

|

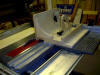

All done except for a finish. It slides and glides beautifully! Really is very easy to use, and a lot cheaper than the Delta Tenoning Jig. |

|

|

|

|

|

|

|

|

|